What is Preventive Maintenance

What is Preventive Maintenance?

Preventative or Preventive maintenance is when you do work to maintain your machine or equipment to prevent an unplanned breakdown. This article will look at defining preventive or preventative maintenance as well as explaining the alternatives that you could use within an industrial setting.

The most common example of preventive maintenance that most people can relate to is that of your car service. Your car service is done at regular intervals based on either time or the distance traveled and the manufacturer defines a series of work that has to be undertaken at each interval. This work can involve changing the oil and coolant to more complicated (and expensive) works such as replacing the timing belt.

The reason for having your car serviced is to try to prevent it from breaking down during use by keeping everything working in as good as condition as possible and to prevent excessive wear. Everything wears over time, especially components that move, hence the need to eventually replace them, in some cases however with components such as your timing belt the consequences of failure can be be very devastating for your engine so we replace these components before they fail rather than face the expense of what happens if they do fail.

The same is true for all machines and equipment within our factories, if we maintain them and have them serviced on a regular basis we can reduce the number of breakdowns that occur and can better rely on our production processes being capable of performing as required.

Why do we need Preventive Maintenance

If we are to supply our customers reliably we will need machines and processes that are available when we need them and running in top condition. Anything less could cause delays and quality problems; not something we want if we are looking to maintain our business.

If we don't do anything with our machines they will eventually fail, often at the least convenient time possible.

Preventive maintenance seeks to ensure that we keep our equipment in good condition by scheduling maintenance to prevent them from breaking down or performance deteriorating.

Breakdown Prevention

Breakdown Maintenance - Run to Failure

Many companies fail to invest in preventive maintenance; waiting for machines to fail and then repairing them rather than spending the money upfront on maintenance. Some people see maintenance as an expense that is there to be minimised and fail to look at the big picture and the costs incurred through the failure to prevent breakdowns.

Breakdowns will often occur at the worst possible time such as when you are desperate to make delivery of a new product to an important customer, unreliable equipment and machines can devastate a companies ability to meet customer demands.

If you had to go on an important trip would you take a car that has done many many miles but has never ever been maintained? Would you trust it to get you where you wanted?

Planned Preventive Maintenance

Planned Preventive Maintenance is a far better option than running to breakdown; you analyse the maintenance requirements for each and every machine and piece of equipment as specified by the manufacturers and through analysis of past breakdown records and create a schedule of required maintenance for each and every machine.

This will give a full list of required maintenance works for each machine based on either time or number of operations and can then begin to plan how you can release each machine for maintenance work to be completed. This is often where many systems fall apart as production fail to release machines when they are scheduled for maintenance as they are "too busy." All the more reason in my mind to release the machines as often the reason for being too busy is due to machine unreliability slowing production!

Weaknesses of Preventive Maintenance

Preventive maintenance works mainly on guesswork, we guess when we will have to replace parts and lubricate. Often the time period (or number of cycles) is based on manufacturers recommendations or on past observations and history.

This does not however take into account how hard the machine has had to work or any variation in the actual parts that we use. We can often find ourselves changing parts that are perfectly good at great expense or changing oil long before it is required, or worse; being too late and the equipment failing before maintenance is performed.

This is why techniques have been developed to monitor the actual condition of equipment; this type of maintenance is called predictive maintenance.

Preventing Breakdowns

Predictive Maintenance Video

Predictive Maintenance

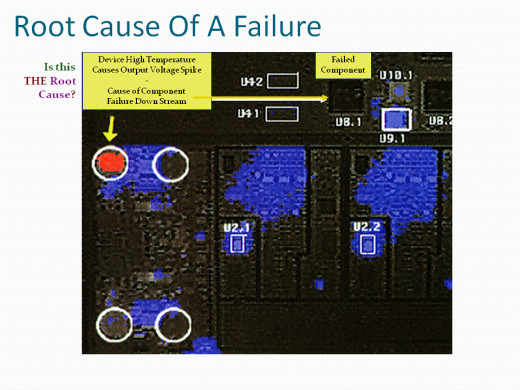

An alternative approach to Preventive maintenance that can be used is that of Predictive Maintenance, we often find with preventative maintenance that we are replacing perfectly usable components in machines through fear that they will break in the very near future despite there being no of few signs of wear and tear.

Predictive maintenance uses various techniques such as Infrared thermal imaging, oil analysis, ultrasonic testing and vibration analysis to try to highlight when components are starting to fail giving us time to schedule maintenance to replace them or make repairs. This allows us to potentially use components for much longer than we would otherwise and to also catch any premature failures.

There is a cost involved in conducting all of this analysis and care should be taken to ensure that this cost does not exceed the likely savings over just using preventive maintenance techniques.

Preventive Maintenance Systems

There are many computer programs out there to use to schedule your preventative maintenance. These programs are able to use elements of predictive maintenance also by keeping track of actual breakdowns and works conducted allowing you to get better cost effectiveness from your maintenance efforts.

These systems can however be expensive and time consuming and rely very much on using your maintenance experts to conduct all works. However there are often works and observations that can be undertaken by the actual people using the equipment; this is where Autonomous Maintenance and Total Productive Maintenance come into play.

TPM Presentation

Operator Led Maintenance

Total Productive Maintenance

Total Productive Maintenance or TPM is part of Lean Manufacturing and seeks to involve everyone in the company in ensuring that maintenance is done in the most effective and economical ways possible. It utilizes preventive and predictive maintenance ideas but will have the operators conducting most of the preventive maintenance items themselves (autonomous maintenance) freeing up the more technical maintenance experts to work on ideas to make machines more reliable and design them so that they are easier to maintain and require less maintenance.

TPM seeks to reduce the six big loses (below) through using operators to conduct basic preventive maintenance such as lubrication and tightening of bolts.

- Breakdowns

- Setup and Adjustment losses

- Idling and minor stoppages

- Reduced Speed

- Defects and rework

- Start-up losses

These loses are measure through the use of something called OEE or overall equipment effectiveness which drives us to use other lean manufacturing tools such as SMED and PokaYoke to prevent defects and reduce setup times and loses.

Preventative Maintenance; a final word

Allowing machines and equipment to run until they breakdown is most cases not a good way to run your business. It is rarely cost effective and more often than not will lead to massive disruptions to your customer. It is important that you implement some form of predictive maintenance system for your assets.

If you have any questions about preventive maintenance or want to make any observations please use the section below.